Ever wondered how Royal Caribbean builds a cruise ship from scratch? We’re talking about floating cities at sea — complete with water parks, Broadway-caliber shows, robot bartenders, and thousands of guests sailing in comfort and style. These mind-blowing ships don’t just appear overnight.

They take years of planning, engineering, testing, and flat-out imagination to bring to life. And for the first time in a long time, Royal Caribbean recently gave us a rare, behind-the-scenes look at what it really takes to go from concept to completed ship.

From that very first spark of an idea to the day guests walk onboard for the maiden voyage, there’s a jaw-dropping amount of work behind every ship you’ve ever cruised on — and some parts might surprise you.

If you’re curious how old each ship is in the fleet, check out our guide to Royal Caribbean ships by age — it’s a fun way to see how long these engineering marvels have been sailing the seas.

In this post, I’ll break down every major step of how Royal Caribbean builds a cruise ship, based on real details from the cruise line, official video footage, and what actually goes on inside the shipyards. I’ll keep it fun, fact-based, and easy to follow.

Whether you’re a loyal Crown & Anchor cruiser or just cruise-curious, this behind-the-scenes walkthrough will give you a whole new appreciation for what it takes to launch the next Utopia, Icon, or Oasis of the Seas.

Table of Contents

It All Begins with a Bold Idea

The process of how Royal Caribbean builds a cruise ship doesn’t start with steel or schematics. It starts with a question: “Who are we building this for?”

This first phase is known as ideation, and it’s all about imagining what the next generation of cruising could look like. Royal Caribbean’s internal teams of designers, engineers, architects, and brand specialists gather in boardrooms, sketching ideas, debating features, and dreaming up never-before-seen experiences.

- Do millennials want more nightlife?

- Do families want multi-generational spaces to relax and play together?

- Can we really fit a surf simulator, zip line, and Central Park into one ship?

These aren’t hypothetical questions. They’re the kind of real conversations that drive the early stages of every new ship in the fleet. Royal Caribbean doesn’t just want to meet guest expectations — they want to exceed them with something totally new and unforgettable.

CEO Jason Liberty summed it up well: “It’s in our DNA to wake up every day dreaming and innovating about what the future experience could look like.”

This is where the magic begins. Before any blueprint is drawn or steel is cut, Royal Caribbean has to dream bigger than anyone else at sea.

Turning Dreams into Designs

Once the brainstorming wraps up, the real work begins. At this point in how Royal Caribbean builds a cruise ship, the focus shifts from ideas to detailed designs, and this is where things get incredibly complex.

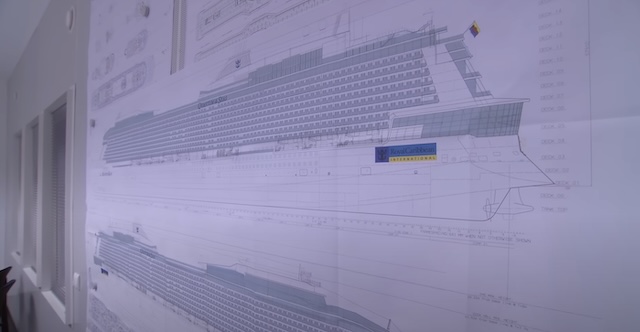

Royal Caribbean invests over a million working hours during the design phase for a single ship. That includes everything from digital renderings and 3D models to blueprints of every hallway, cabin, and engine room. It’s not just about aesthetics, it’s about efficiency, safety, innovation, and experience.

Every corner of the ship has to be mapped out. The placement of a stairwell can affect passenger flow. The angle of a balcony can influence wind resistance. Even the height of a buffet sneeze guard is taken into account. Nothing is random. Everything is intentional.

And it’s not just internal teams doing this work. Royal Caribbean collaborates with naval architects, marine engineers, and even psychologists to optimize layout and guest experience.

This step is crucial because you can’t build what you haven’t fully planned. Before a single piece of steel is cut, the entire ship must exist on paper, screen, and simulation.

In short, how Royal Caribbean builds a cruise ship depends on a rock-solid design phase, and they take it seriously.

Choosing the Right Shipyard

Not every shipyard can handle the scale and complexity of building a modern cruise ship. And when it comes to how Royal Caribbean builds a cruise ship, choosing the right shipyard is a make-or-break decision.

Royal Caribbean typically partners with a select few shipyards in Europe, especially Meyer Turku in Finland and Chantiers de l’Atlantique in France. These yards are some of the only facilities in the world equipped to build ships that carry 5,000 to 7,000 guests, feature water parks, entertainment venues, and cutting-edge propulsion systems — all in a floating structure the size of a skyscraper laid on its side.

Once the blueprints are finalized, the cruise line selects a yard based on factors like:

- Ship size and class

- Delivery timeline

- Technological capabilities

- Yard availability and labor force

This step in how Royal Caribbean builds a cruise ship also includes one of the most symbolic moments in the entire process: the steel-cutting ceremony. This is when the first sheet of steel is sliced, often with fanfare, media, and a silhouette of the ship cut from that steel as a memento.

From that moment on, the countdown is officially on. The project shifts from digital renderings to real-world construction, one steel plate at a time.

Block by Block: Building the Ship’s Skeleton

Now we’re into the heavy lifting. At this stage of how Royal Caribbean builds a cruise ship, the action moves into the dry dock — and the ship begins to physically take shape.

Cruise ships aren’t built like buildings. Instead of being constructed from the ground up in one piece, they’re assembled from massive blocks. These blocks are prefabricated off-site using steel, wiring, plumbing, and basic structural components. Once complete, they’re transported to the shipyard and lifted into place like pieces of a giant 3D puzzle.

The very first block placed is the keel, a foundational structure that acts like the ship’s spine. During the keel-laying ceremony, a pair of lucky coins is placed beneath it — a centuries-old maritime tradition symbolizing good fortune and smooth sailing.

Once the keel is laid, block after block is added. With each new section, the ship’s silhouette becomes more recognizable. Eventually, a rough outline of the ship forms, complete with a bow, stern, and towering superstructure.

This block-based approach allows Royal Caribbean and the shipyard to work on multiple sections of the ship simultaneously, saving time and improving quality. Every single block — from engine rooms to entertainment spaces — is built with precision.

At this point, how Royal Caribbean builds a cruise ship becomes less about drawings and more about actual steel, sweat, and serious machinery.

Welding, Wiring, and Heavy Engineering

With the ship’s skeleton in place, this stage of how Royal Caribbean builds a cruise ship is all about bringing the vessel to life, one cable, one weld, and one system at a time.

This phase spans over a year and involves an enormous amount of technical work. Think miles of wiring, hundreds of AC ducts, giant propellers, and powerful engines, all installed with the kind of precision you’d expect from a floating city.

Here’s what happens during this engineering-heavy stretch:

- Welding thousands of seams to ensure watertight integrity

- Running electrical systems through every corridor and stateroom

- Installing plumbing for bathrooms, kitchens, pools, and spas

- Connecting propulsion and steering systems to the engines

- Mounting stabilizers that reduce the ship’s motion at sea

What makes this part especially impressive is that many of these systems are installed while the ship is still in pieces. Sections are worked on independently, then joined together like a seamless puzzle.

Behind every perfectly chilled stateroom and smooth ride across the Caribbean is this intense engineering effort. It’s a reminder that how Royal Caribbean builds a cruise ship isn’t just about big ideas, it’s about executing those ideas with military-level precision.

Cabins, Cranes, and Careful Placement

While the ship’s hull and systems are coming together, another major piece of how Royal Caribbean builds a cruise ship is happening nearby, the cabins.

Rather than building staterooms onboard, Royal Caribbean uses an industrialized, modular approach. Each cabin is pre-fabricated off-site, complete with walls, lighting, bathrooms, and even furniture. These fully assembled rooms are then lifted into place using cranes, one by one, like perfectly sized building blocks.

This process takes about a year from start to finish and allows for tighter quality control, faster installation, and more efficient construction overall. Every cabin is built to fit exactly into its assigned space, whether it’s an inside room or an oceanview balcony.

Meanwhile, teams are also working on:

- Public venues like restaurants, theaters, and lounges

- Crew areas and technical zones

- Staircases, elevators, and corridors connecting the entire ship

It’s not just about fitting things in, it’s about precise coordination between dozens of teams, vendors, and shipyard workers. One missed measurement could throw off entire decks.

When you walk into your stateroom and everything feels seamless, it’s because months of planning and placement made it that way. This stage of how Royal Caribbean builds a cruise ship proves that even the smallest details require massive effort.

Float Out: The Big Moment

After years of planning, welding, and lifting, this is the milestone that makes jaws drop — the float out. It’s one of the most visually stunning steps in how Royal Caribbean builds a cruise ship, and it’s exactly what it sounds like.

Until now, the ship has been assembled in a dry dock, a massive basin where construction can happen safely without water. But once the outer structure is complete, it’s time to let the ship touch water for the very first time.

The dry dock is slowly filled, and the ship rises off its supports and begins to float. It finally looks like a real vessel — with a bow, stern, and hull ready to take on the ocean.

This moment is symbolic and practical. It marks the end of the heavy structural phase and the beginning of final outfitting. At this stage, work is still happening around the clock to prepare for sea trials, but seeing the ship float for the first time is a turning point.

There’s no turning back now. Once a ship floats, it stays afloat for good. In the process of how Royal Caribbean builds a cruise ship, this is the part where imagination officially becomes reality.

Sea Trials: Testing Every System

Now that the ship is afloat, it’s time to prove she can perform. This phase of how Royal Caribbean builds a cruise ship is called sea trials, and it’s essentially the ship’s first test drive, except way more intense.

Sea trials usually last several days and are conducted out at sea with hundreds of engineers, technicians, and inspectors onboard. These experts aren’t sipping piña coladas on the pool deck. They’re evaluating every system under real-world conditions.

Here’s what gets tested:

- Engine performance and fuel efficiency

- Steering, propulsion, and navigation systems

- Emergency response protocols and alarms

- Stabilizers and maneuverability

- Speed under various loads and weather

These tests go beyond safety, they’re about verifying performance guarantees set in the ship’s design contracts. The ship needs to hit specific benchmarks in speed, responsiveness, and handling. If it doesn’t, adjustments are made before the ship can move on.

Some of the most critical systems on board can’t be properly tested at the dock, which is why this stage is non-negotiable.

Once sea trials are successfully completed, the ship is cleared for the final round of work before guests ever step onboard. How Royal Caribbean builds a cruise ship isn’t just about creating a beautiful vessel, it’s about making sure that ship performs flawlessly out at sea.

Final Touches and the First Guests

After sea trials, you might think the ship is done — but not quite. The final stage of how Royal Caribbean builds a cruise ship is all about polishing the experience and getting the ship fully guest-ready.

This period is often referred to as owner’s work. While the ship is now technically complete and has passed all engineering checks, Royal Caribbean uses this time to make last-minute changes, enhancements, and cosmetic improvements. These can include:

- Installing signage, artwork, and décor

- Stocking bars, kitchens, and onboard shops

- Programming lighting, A/V systems, and touchscreen tech

- Deep-cleaning every venue, cabin, and corridor

- Testing and fine-tuning guest-facing experiences

This is also when furniture is loaded, venues are styled, and everything starts to look and feel like the Royal Caribbean experience we all recognize. If a venue layout isn’t flowing quite right or if a new attraction needs some tweaking, this is the time to fix it.

The crew also boards and begins training, running drills, learning systems, and preparing for their specific roles. Every bartender, stateroom attendant, and officer needs to be ready to deliver a flawless experience on day one.

When that final lightbulb is screwed in and the last buffet sneeze guard is wiped clean, it’s time. How Royal Caribbean builds a cruise ship officially wraps as the first guests step onboard — wide-eyed and ready for adventure.

How Long Does It Take to Build a Royal Caribbean Ship?

If you’re wondering how long this entire process takes — the answer might surprise you. How Royal Caribbean builds a cruise ship is not a quick endeavor. From the very first brainstorming session to the moment the ship welcomes its first guests, the entire timeline can stretch across five to seven years.

Here’s a rough breakdown of what that looks like:

- Ideation and concept development: 1–2 years

- Engineering and detailed design work: 1.5+ years

- Construction and assembly: Around 3 years

- Float out and sea trials: A few weeks total

- Final outfitting and owner’s work: Several weeks before delivery

Each phase builds on the last, and decisions made in year one might not actually impact guests until year five or six. That’s part of what makes Royal Caribbean’s shipbuilding strategy so impressive — they’re designing for a future cruise experience that doesn’t even exist yet.

So next time you’re walking down the Royal Promenade, sipping a cocktail in the Solarium, or watching a show in the AquaTheater, just remember: that moment was years in the making.

Jim’s Take: Why This Process Blows My Mind

Growing up cruising, I was always focused on the fun — the pools, the buffets, the ports, the freedom. But as I’ve gotten older, I’ve started to look at cruising through a different lens. Now I find myself asking bigger questions, like how Royal Caribbean builds a cruise ship in the first place. And honestly? I’m blown away.

I never truly appreciated just how many people, how much creativity, and how many years it takes to bring a ship to life. Watching Royal Caribbean design and deliver these floating cities with such precision makes you realize this isn’t just a business — it’s a passion project at scale.

What would it even be like to work at Royal Caribbean and help build one of these ships? To be part of the team imagining new neighborhoods, designing the first-of-its-kind attractions, and solving massive engineering challenges? It’s clear they’re not just thinking outside the box. They’re redefining what’s possible at sea.

The Icon Class ships are a perfect example. Waterslides, surf simulators, indoor aquadomes, and entire family neighborhoods — all on one ship? It’s not just exciting. It’s revolutionary.

If you want to see just how massive some of these ships really are, check out my deep dive into Royal Caribbean ships by size — the numbers alone are mind-blowing.

I have a newfound appreciation for every inch of space, every decision, and every detail. Next time I walk onto a Royal Caribbean ship, I’ll be thinking not just about where I’m going — but about how this incredible machine came to be.

What Part of the Shipbuilding Process Surprised You Most?

I’d love to hear your thoughts. Did you know it takes millions of work hours and five to seven years to build one Royal Caribbean ship? Or that cabins are fully built off-site and lifted onto the ship like giant Lego pieces?

Drop a comment below and let me know:

- What surprised you the most?

- Would you ever want to help build a cruise ship?

- Or… are you just happy someone else did the work so you can enjoy the hot tub?

I read every comment, so don’t be shy — let’s talk cruise ships!